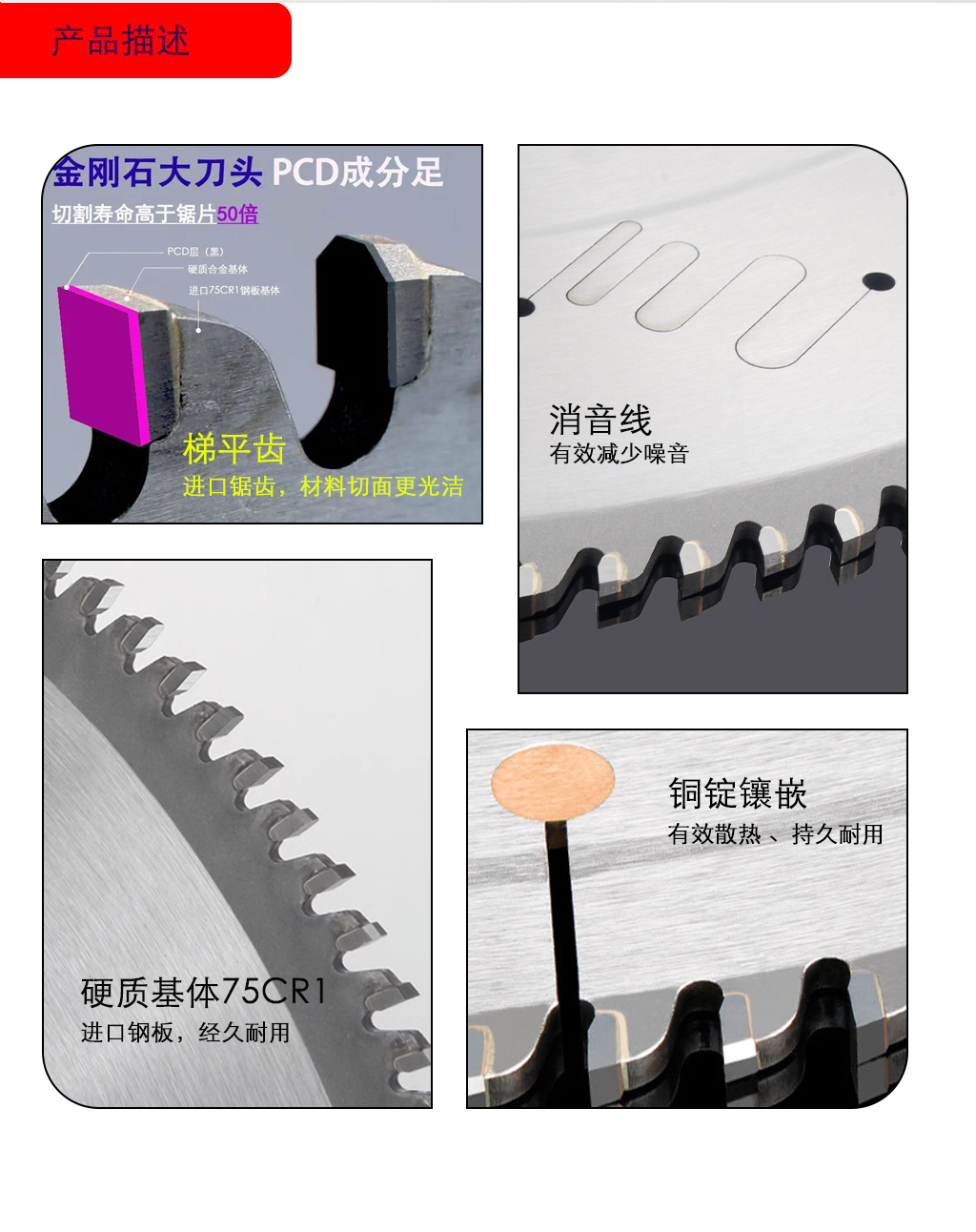

I. Core Advantages of PCD Diamond Saw Blades in Aluminum Processing

Aluminum materials (including pure aluminum and aluminum alloys) are classified as soft non-ferrous metals, featuring low hardness (Mohs hardness of 2.5-3 for pure aluminum and approximately 2.8-4 for aluminum alloys), good plasticity, and a tendency to stick to tools. The performance of PCD saw blades can precisely address the pain points in aluminum processing:

- Smooth cutting surface with no burrs or collapses

The PCD cutting edge is sharp and flat (with a roughness as low as Ra0.1μm or below). When cutting, it can quickly cut off the metal fibers of aluminum materials, avoiding “tearing”, “burrs”, or “edge collapse” caused by the high plasticity of aluminum. For example, when cutting aluminum alloy profiles, assembly-level surface precision can be achieved without subsequent grinding, reducing secondary processing procedures. - Extremely wear-resistant with a long service life

Although aluminum is soft, chips are prone to causing “adhesive wear” due to friction with tools during processing (aluminum chips easily stick to the cutting edge to form “built-up edges”, leading to blunting of the edge). However, PCD materials have an extremely low friction coefficient (0.1-0.3) and much higher hardness than aluminum (Mohs hardness of PCD is 9.8-10). They are not easy to stick to chips and wear very slowly. Their service life is 20-50 times that of traditional high-speed steel saw blades and 5-10 times that of cemented carbide saw blades, which can significantly reduce the frequency of saw blade replacement and is suitable for mass processing. - High cutting efficiency and fast feeding speed

PCD saw blades have low frictional resistance and can adopt a higher feeding speed during cutting (for example, when cutting aluminum alloy plates, the feeding speed can be 1.5-3 times that of cemented carbide saw blades). Moreover, the cutting edge remains sharp for a long time, avoiding efficiency reduction due to wear. For instance, in mass cutting of aluminum profiles, it can significantly increase the processing volume per unit time, making it suitable for industrial assembly line production. - Narrow kerf and high material utilization

PCD cutter heads can be designed with thinner cutting edges (minimum kerf width can be as low as 0.3-0.5mm), which can reduce material waste compared with traditional saw blades (usually with a kerf of 1-2mm). For high-value aluminum materials (such as aviation aluminum alloys), this advantage can directly reduce material costs. - Low cutting temperature and reduced aluminum oxidation

PCD has a low friction coefficient, generating less heat during cutting. When combined with a cooling system (such as water cooling), the temperature can be further controlled, avoiding surface oxidation and discoloration of aluminum due to high temperatures (such as blackening of the surface of aluminum alloys after cutting). It is especially suitable for products requiring high surface finish (such as decorative aluminum materials and electronic aluminum parts).

II. Main Application Scenarios

PCD diamond saw blades are used in aluminum processing, focusing on fields with high added value and high precision requirements, specifically including:

- Cutting of aluminum alloy profiles

- Application: Fixed-length cutting of architectural aluminum profiles (door and window frames, curtain wall profiles) and industrial aluminum profiles (mechanical equipment guide rails, brackets);

- Advantage: The cut end face of the profile is flat and can be spliced without subsequent grinding, improving assembly efficiency.

- Cutting of aluminum sheets/aluminum foils

- Application: Slitting of thick aluminum sheets (such as 5-50mm aviation aluminum sheets) and precision cutting of thin aluminum foils (such as aluminum foils used in the electronics industry);

- Advantage: The kerf is narrow and free of burrs, avoiding defects in subsequent processing (such as stamping) of aluminum foils caused by burrs.

- Processing of aluminum parts

- Application: Cutting of automotive aluminum alloy parts (such as engine casings, wheel blanks) and electronic aluminum parts (such as heat sinks, aluminum casings);

- Advantage: High cutting precision (dimensional error can be controlled within ±0.05mm), which can directly serve as a preprocessing step for subsequent processing (such as milling and drilling).

- Cutting of aluminum materials in composite materials

- Application: Cutting of aluminum-plastic composite panels and aluminum-wood composite profiles;

- Advantage: PCD has good cutting performance for both aluminum materials and non-metals (plastics, wood), and can complete the cutting of composite layers at one time, avoiding delamination or edge damage.

III. Precautions for Application

Although PCD saw blades are suitable for aluminum processing, attention must be paid to their characteristic limitations to avoid reduced efficiency or saw blade damage due to improper use:

- Avoid cutting high-silicon aluminum alloys (special design required)

Some aluminum alloys (such as cast aluminum alloys) have a high silicon content (silicon content > 10%). Silicon particles have high hardness (Mohs hardness 7), which will accelerate the wear of the PCD cutting edge. In this case, it is necessary to select coarse-grained PCD cutter heads (more wear-resistant) or specially designed wear-resistant PCD saw blades, and reduce the feeding speed at the same time. - Cooling system must be used

Aluminum has high plasticity and is prone to generating “built-up edges” (aluminum chips sticking to the cutting edge) during cutting. Although PCD has better anti-sticking performance than other tools, it is still necessary to flush the chips and cool down through cooling (such as emulsion and cutting oil) to avoid built-up edges affecting cutting precision. - Control cutting parameters

- Linear speed: It is recommended to be 30-60m/s (adjust according to the hardness of aluminum materials; it can be higher for soft aluminum and slightly lower for hard aluminum alloys);

- Feeding speed: Adjust according to the diameter of the saw blade and the thickness of the aluminum material to avoid vibration or impact damage to the cutting edge caused by excessively fast feeding;

- Base selection: Priority is given to alloy bases with good rigidity to reduce cutting vibration (aluminum is soft, and vibration is likely to cause “wavy” defects on the edge).

- Avoid cutting special aluminum materials containing elements such as iron and nickel

If aluminum materials contain a large amount of iron and nickel (such as some superalloys), metal elements may react with diamond in PCD at high temperatures (forming carbides) during cutting, accelerating the wear of the cutting edge. In this case, cemented carbide saw blades are more suitable.

IV. Comparison with Other Aluminum Cutting Saw Blades

| Saw Blade Type | Surface Quality | Service Life | Application Scenarios | Long-term Comprehensive Cost |

|---|---|---|---|---|

| PCD Diamond Saw Blade | Optimal (no burrs) | Longest (20-50 times) | High-precision, mass processing (such as profiles, parts) | Low (reduced replacement) |

| Cemented Carbide Saw Blade | Medium (slight burrs) | Shorter | Ordinary aluminum materials, low-precision processing | Medium (frequent replacement required) |

| High-speed Steel Saw Blade | Poor (prone to burrs) | Shortest | Small-batch, low-hardness pure aluminum processing | High (short service life) |

Summary

PCD diamond saw blades, with the advantages of “high surface quality, long service life, and high efficiency” in aluminum processing, are especially suitable for scenarios with mass production and high precision requirements (such as architectural profiles, auto parts, and electronic aluminum parts). Although the initial purchase cost is higher than that of cemented carbide saw blades, it can achieve “cost performance improvement” in long-term use by reducing replacement frequency and lowering secondary processing costs. As long as attention is paid to cooling, parameter control, and material adaptability, its performance advantages can be fully exerted.