PERFORMANCE OVERVIEW

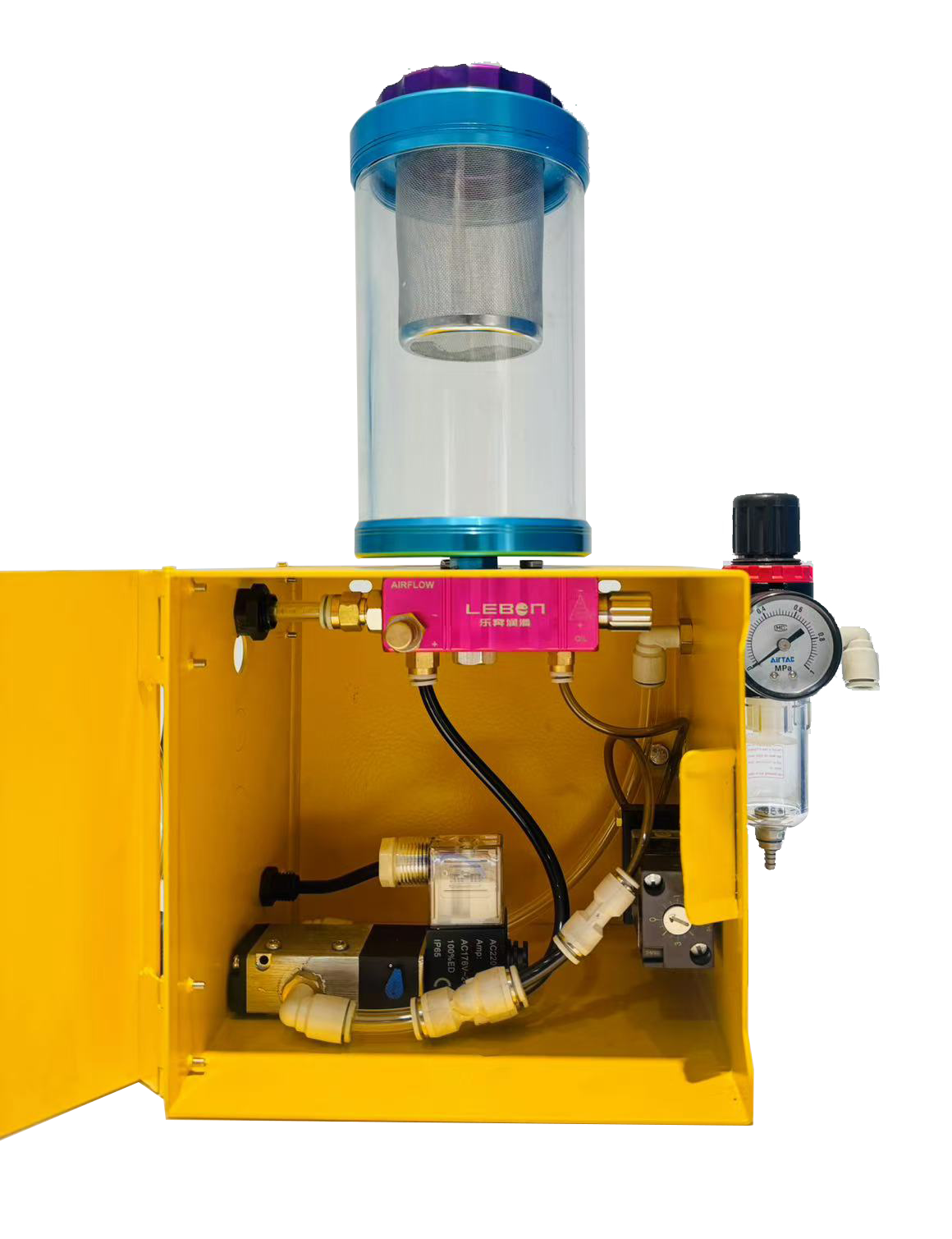

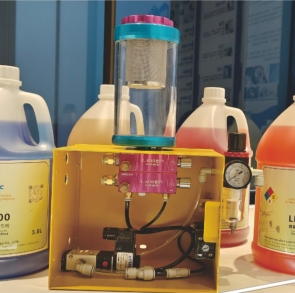

After the compressed air passes through the filter pressure reducing valve, the two – position two – way solenoid valve controls the opening of the air source, which can be synchronized with the equipment processing. The pneumatic frequency generator is used to control the work of the pneumatic oil. After the compressed air is introduced, the gas – liquid booster piston increases the oil pressure and discharges it to the metering parts. Each metering part discharges the dripping oil quantitatively, and after passing through the mixing valve, it is driven by the compressed air to spray to each lubrication point.

PRODUCT USE

The Leben micro – lubrication energy – saving system can accurately spray the lubricating oil to the cutting interface through adjustment. The lubricating oil is sprayed onto the cutting port extremely accurately through air pressure.

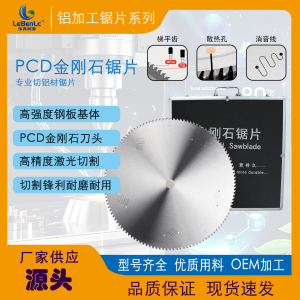

Applicable equipment: aluminum finished saw, circular saw cutting machine, aluminum cutting machine, band saw, comb – tooth cutting machine, small machining center (mold processing) general cutting machine, punching machine, broaching machine, hobbing machine (hob) rolling machine, milling machine, drilling machine, special machine.

PRECAUTIONS

It is recommended to use Leben oil to check the injection system regularly to prevent other impurities from entering and clogging the nozzle, affecting the use effect.

Main Accessories